Product description

Since the moveable parts are not surface treated, i.e. not case hardened, the possibilities of application of these universal joints are much more limited compared to the ones made of standard steel. Therefore, the guide lines for the selection of universal joints with friction bearing according to the diagram may be applied at a limited extent only. Rotational speeds over 200 min may become critical.

For continuous use of the stainless steel universal joints, ample lubrication is very important. This achieved by fitting the joint with a grease filled gaiter GN 808.1.

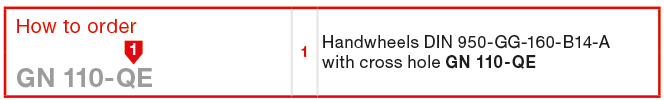

The order example refers to universal joints with equal bores both ends d2 or s.

Specification

Stainless steel AISI 304NI

RoHS

Accessory

Gaiters GN 808.1 (for universal joints)

On request

With other or unequal bores