More than standard

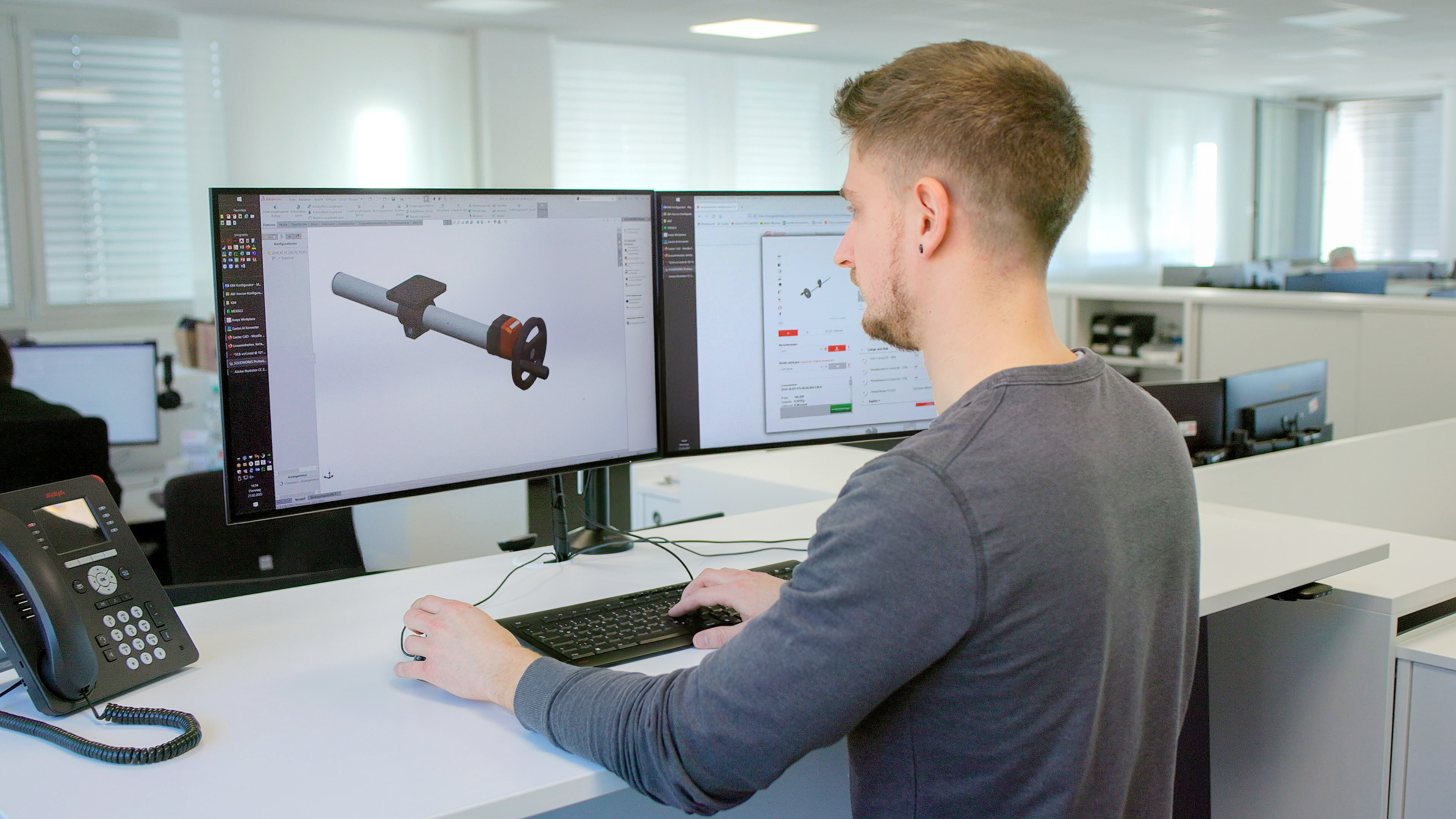

Customised products are very much part of Ganter's core competence. In spite of the enormous range of different standard parts, there'll always be highly specific requirements in terms of dimensions, materials or functions. Working closely with the customer, Ganter goes to work to develop individual solutions.

New or adapted

Depending on requirements, customised parts and elements are made by cost-effectively adapting an existing Ganter standard part – or by going all the way back to the drawing board.

Flexible manufacturing options

A unique wealth of different production methods and a flexible, customer-driven organisation allow standard parts to be customised.

Full service benefit

Ganter not only develops and produces customer-specific parts, but also handles their stockkeeping on call, if requested. This guarantees economical lot sizes, favourable prices and a high degree of security of supplies.

Some Examples

- Cabinet "U" handles, asymmetric in shape, made of elliptical aluminium profile sections

- Adjustable hand lever with individually designed handle element made of die-cast zinc

- Rotary buttons made of black anodised aluminium profile sections with user-specific laser engraving

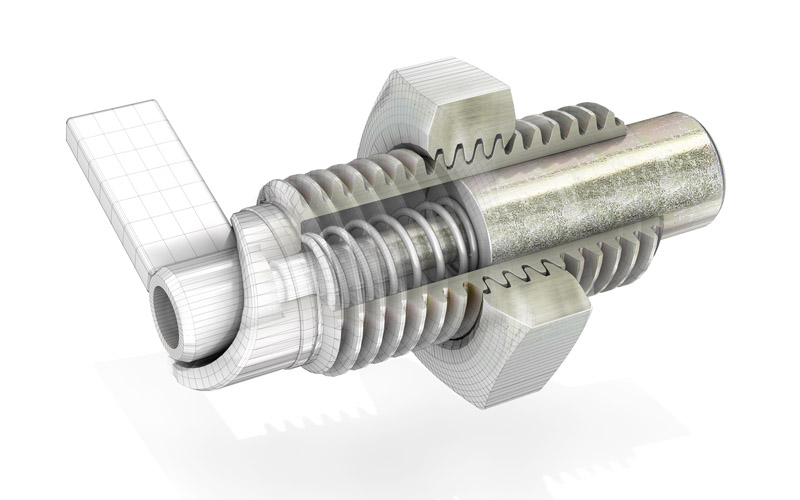

- Special indexing plunger made of stainless steel with red plastic knob