Aluminum Profile Systems Designed for User-Friendliness

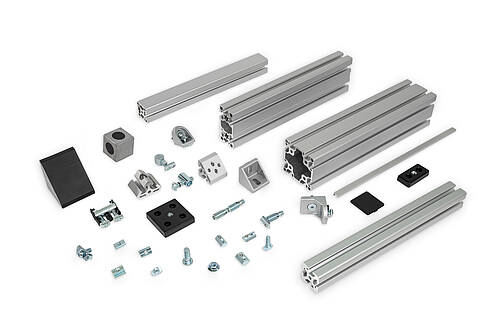

Ganter always thinks in terms of applications – that is the great strength of the market leader in standard parts. The same is true for the newest additions to the product portfolio: system-based aluminum profiles. The anodized, extruded profiles match the dimensions and properties of the longstanding systems of Bosch and Item, with heavy and light versions, a variety of cross-sections, dimensions and slot arrangements.

For some time, Ganter’s product range has included many key elements for the custom use of profile systems. These include diverse angle brackets, T-nuts and everything else for attaching parts directly and indirectly to modular profile constructions: U-handles, hinges, panel support clamps and leveling feet, just to list a few examples.

Now the profiles themselves are included, as are specific connecting elements and other parts, such as cover and edging profiles, end caps, joints and foot plates. Thanks to these additions, it is now possible to build entire fixtures, machines, systems or workstations with Ganter parts – with no need to order additional parts from other suppliers, making procurement simpler and more efficient.

The same is true for handling of the profiles themselves: Here, Ganter intentionally departs from the previously typical practice of offering the profiles exclusively in the form of 6 meter long bars. Instead, the profiles can be ordered in all cross-sections in lengths of 2 or 3 meters – delivered in practical bundles. This yields a number of advantages: First, the products can be shipped via fast parcel services. Second, it is easier to handle profiles cut to individual lengths. And third, special storage spaces are not required for profiles that are not yet needed.

On its website and in its catalog, Ganter provides detailed instructions for the assembly of the new elements as well as any necessary modifications – and easily followed video tutorials will soon be available to make this content even easier to access.

Back